|

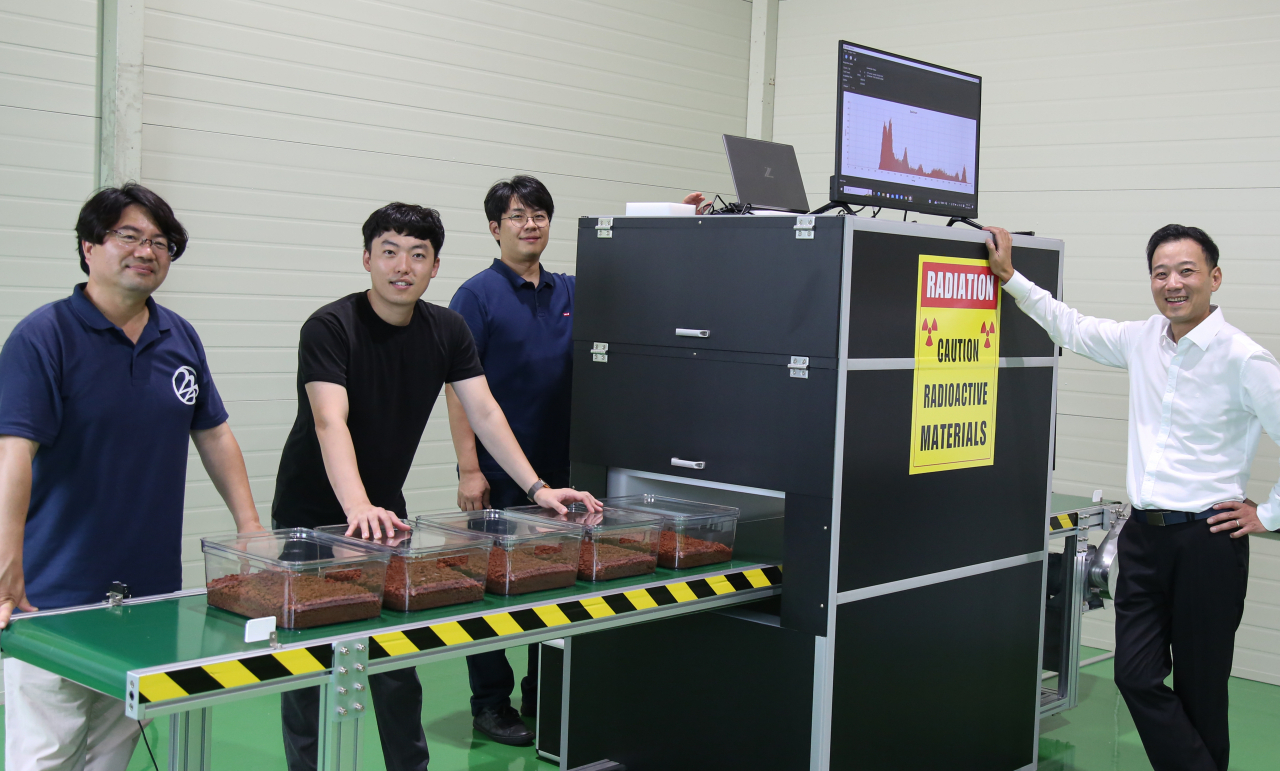

The 3I Solutions team poses for a picture next to the newly developed Industrial Neutron Composition Analyzer. (Hyundai Steel) |

Hyundai Steel, in collaboration with Hyundai Motor Group's in-house startup 3I Solution, has developed an Industrial Neutron Composition Analyzer that accelerates steel manufacturing by evaluating raw materials, such iron ore and scrap metal, in real time.

By providing real-time feedback, it allows Hyundai Steel to quickly achieve the right balance in their materials, sometimes referred to as optimal chemical composition. This balance not only ensures the consistent quality of the steel produced but also reduces waste and costs.

Previously, determining the right balance of these materials took around eight hours from the time a sample was taken to when it was inspected. The new analyzer expedites this process, using a method that detects specific gamma rays emitted by different elements when they are exposed to neutrons. It is analogous to a faster, more advanced scanner for raw materials.

The push for this technology began in 2018 when Hyundai Steel investigated ways to improve how they grade and use recycled metal, or ferrous scrap.

By 2021, the project had caught the attention of Hyundai Motor Group's startup team, 3I Solution, where 3I is an acronym for "Innovation of Invisible Inspection." It led to over two years of research and development. With the analyzer's performance verification now complete, plans for an independent spin-off are on the horizon.

Beyond steel, 3I Solution is also looking to adapt similar technology to tap into the booming battery recycling industry. They are working on a product that employs neutron activation analysis to measure concentrations of metals such as lithium and nickel in battery waste powder and repurpose them for new batteries.

“While five foreign companies control 75 percent of the neutron analyzer market, our focus is to present an alternative by offering solutions tailored to specific local needs at a more competitive price point," an official from 3I Solution said.

The deployment of the new analyzer is under active consideration by Hyundai Steel. If integrated, it could yield significant cost savings by fine-tuning material combinations and collecting in-depth data insights.

The company also anticipates that tools like the analyzer, which facilitate upscale iron scrap analysis, will become increasingly vital as the industry gravitates towards carbon-neutral manufacturing.

![[KH Explains] Samsung chief says he is still ‘hungry’ for foundry growth](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=644&simg=/content/image/2024/10/08/20241008050604_0.jpg)