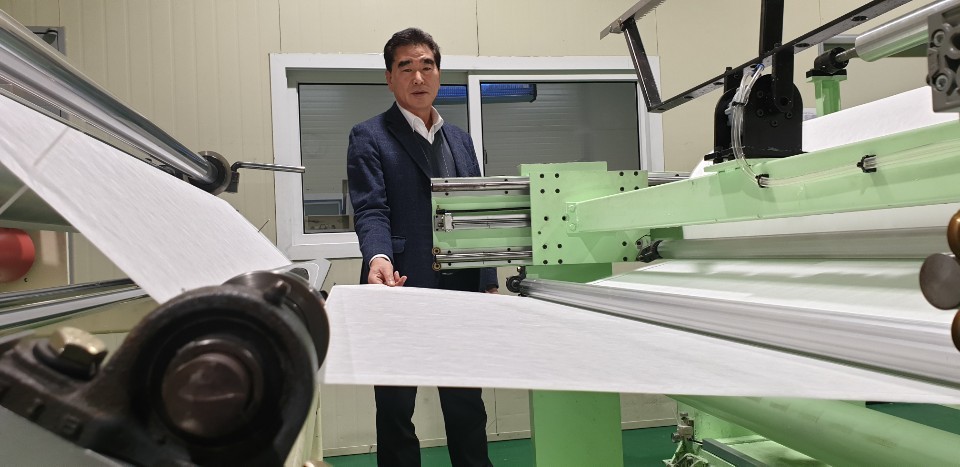

POCHEON, Gyeonggi Province -- Amid coronavirus fears, local fabric maker Environment & Human’s machines have been in full operation night and day.

The non-woven fabric manufacturer churns out thin sheets of meltblown non-woven fabric, an essential material for face masks.

Demand for masks has been skyrocketing, driving the government to take full control over the supply and distribution of masks. The surge -- likely to continue for some time -- reflects concerns about the virus but it also offers a big opportunity for local mask manufacturers like E&H.

“Within just two business days after the Lunar New Year holiday last month, the company was inundated with two months’ worth of orders,” said Hwang Kyu-ik, founder and president of E&H, forecasting the upward trend in demand would continue and boost sales this year.

Founded in 2001, the company produces the meltblown non-woven fabric for masks, air conditioner filters, and automotive filters.

The annual production volume of the five production lines installed at its Pocheon plants amounts to more than 30 million square meters of the fabric based on polypropylene. Electrostatically charged, the material absorbs dust, bacteria and pollen. It can be used in filters for fine particles, insulators, diapers and medical masks.

Although soaring orders -- from both Korea and global markets -- mean financial benefits, Hwang said the company would not try to profiteer from the risks and concerns stemming from the virus outbreak.

“Businessmen should not take advantage of other people’s suffering, and I keep emphasizing that to my employees too,” said the president, vowing not to raise the prices of the material to make more profits.

The company is listed on Konex, a securities exchange for small and medium-sized enterprises and venture companies. With the aim of attracting more investments, it plans to move to the nation’s secondary Kosdaq bourse as early as the latter half of this year.

E&H’s sales stood at 17 billion won ($14 million) last year, and the figure is expected to reach some 30 billion won this year on increasing demand for the petrochemical fabric in diverse industries, according to Hwang.

The entrepreneur also envisaged his longtime dream of developing fireproof nonwoven fabric that can prevent fires from spreading quickly at an initial stage.

“Considering my old age, it may be a long shot to make a huge investment, approximately 10 billion won, to develop such incombustible fabric,” the 64-year-old said.

“The product, however, will be worthwhile, as it can be used in schools, apartments and trains to protect people’s lives,” he said.

Despite soaring demand these days, the past few years had been tough for the company.

Nearly half of the five production lines owned by the firm had been idling for three years from 2017 to 2019 because of lukewarm demand, which resulted in stagnating revenue.

However, the company took a bet at the time by investing 32 billion won ($26.5 million) to beef up the production lines and hiring new employees.

With concerns growing over the new coronavirus, demand for face masks has grown exponentially.

On Jan. 20, Korea saw its first confirmed case of COVID-19, the disease caused by the new coronavirus. The number of infections here surpassed 500 on Sunday morning.

Some domestic and Chinese merchants were reportedly buying a large amount of masks, causing a shortage of the products and higher prices here.

Hwang said the recent jump in mask prices was mainly due to merchants behaving like “amateurish crooks.”

“E&H thinks about sustainability first, not short-term profits,” he said.

By Kim Young-won (

wone0102@heraldcorp.com)