Technological prowess puts small Korean firm on global industry map

The Korea Herald, in collaboration with the Korea Environmental Industry & Technology Institute, is presenting a series of articles introducing small but promising environmental tech firms. The following is the third installment. ― Ed.

On the industrial battlefield, tiny dust particles can make a huge difference. They can chip away at employee productivity, optimal machine performance and even cause serious industrial accidents, such as explosions.

This notion, though well accepted by business leaders now, is surprisingly new. The world is, in fact, just starting to learn about dust’s far-reaching impact on the economy and the environment, while it has been for many years talking about crises of all sorts ― climate, food, water and energy.

J-E Tech has put its money and faith behind the importance of dust control, since its foundation 17 years ago.

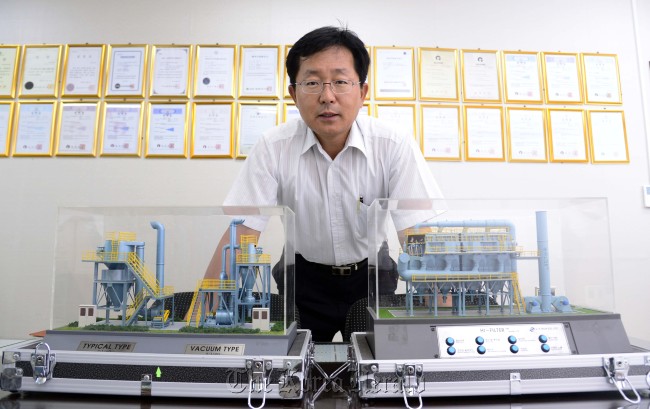

“Until not too long ago, factories in Korea paid little attention to dust control. They spent money on dust collectors, but that was just to avoid penalties, not out of genuine environmental or business-related concerns,” said Jang Du-hun, founder and CEO of the firm.

The competitiveness of a dust collector product would be in its price, effectiveness in purifying the air, maintenance costs, compact size and so on. But when Jang first started his business, price and non-product factors, such as business relations with the manufacturer, decided what a factory chose, he recalled.

“It was a tough market to have faith in.”

Over the years, however, the level of awareness of dust problems among business owners changed greatly. Regulations toughened in Korea and around the world.

“Nowadays when a company designs a new plant, it wants to apply the strictest air control standards, way past the regulations in place, and look for the most up-to-date technologies and systems,” he said.

Reaping the fruits of its past investment, J-E Tech is now fast expanding its domestic market presence with its technological prowess.

One of its key products is the Hi-Filter system, which is suitable for large combustion facilities such as thermal power plants. Combining electrostatic dust-collecting technology and conventional pass-through filters, the system reduces operating and maintenance costs by 30 percent, while removing 99.98 percent of “fine” dust particles, as small as one-fortieth the width of a human hair. Particulate matter less than 2.5 micrometers in diameter, or PM2.5, are referred to as fine.

Cy-Bag Filtration System is another innovative product by J-E Tech, which is expected to bring in a steady stream of revenue for some time.

The facility, specially designed for facilities with coal-fired boilers, such as coal-fired power plants, greatly improved efficiency in the collection of coal dust in damp air.

Coal dust containing high moisture often clogs conventional dust-collecting facilities, forcing them out of operation for about a week every month. But Cy-Bag has operated without stopping for over two years since it was installed in 2010 in a coal-fired power plant, the company said.

The authorities recently chose Cy-Bag as a standard dust collection technology to be used in coal-fired power plants in Korea, a major boost for J-E Tech.

Emboldened by its domestic success, Jang is now aggressively targeting overseas markets, particularly the fast-growing Chinese market.

J-E Tech won its first Chinese contract, worth 2 billion won ($1.7 million), in 2009 with the Hi-Filter system. It landed orders for its Cy-Bag products, worth 7 billion won last year.

“For companies like us, strong in technology but weak in brand recognition, the Chinese market is very favorable,” he said. “Chinese clients want the newest technologies and best-performing products.”

R&D remains the top priority for the firm, Jang said.

“To ensure future growth, we’re investing in technologies and products in two key areas ― asbestos cleanup and a new catalyst to break down airborne pollutants,” he said.

J-E Tech, unlisted, reported revenues of 8 billion won in 2011, a 97 percent increase from a year ago. This year, it aims for 15 billion in revenues.

By Lee Sun-young (

milaya@heraldcorp.com)

![[Herald Interview] 'Trump will use tariffs as first line of defense for American manufacturing'](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=644&simg=/content/image/2024/11/26/20241126050017_0.jpg)

![[Health and care] Getting cancer young: Why cancer isn’t just an older person’s battle](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=644&simg=/content/image/2024/11/26/20241126050043_0.jpg)