|

Lee Dal-hoon, vice president and head of the battery management system R&D center at LG Energy Solution, outlines the company's BMS business history at BatteryDay 2024, held at Coex in Seoul this May. (LG Energy Solution) |

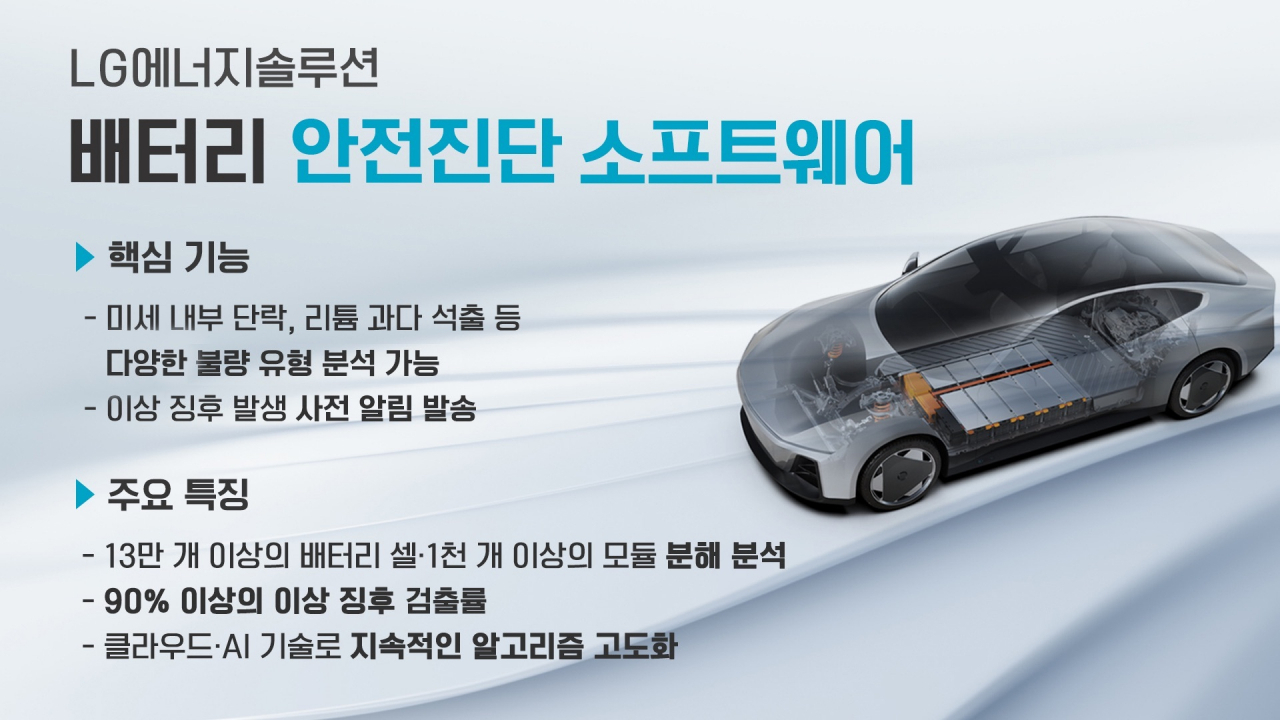

LG Energy Solution said Wednesday it is expanding its battery safety diagnostic software business in response to the rising demand from electric vehicle manufacturers for more advanced safety measures.

"With the recent EV fires, automakers are under pressure to enhance battery safety, but developing reliable diagnostic software is both complex and resource-intensive. LG Energy Solution is in a strong position here -- we have the diagnostic capabilities, the patents, and the real-world data. We will now partner with more automakers to expand our BMS business and help ensure the safety of EV batteries," an official from LG Energy Solution said.

Traditionally, battery diagnostic systems have struggled with accuracy in real-world conditions, largely because they have been built on theoretical scenarios. LG Energy Solution draws on over 20 years of hands-on expertise in battery management system, or BMS, technology. With a database that includes analysis of more than 130,000 battery cells and over 1,000 modules, LG posits that its safety diagnosis software is backed by solid empirical evidence. The technology has already been implemented in more than 100,000 electric vehicles, achieving a safety diagnosis detection rate of over 90 percent.

|

(LG Energy Solution) |

The software is designed to detect a range of potential battery issues, such as voltage drops during charging, internal short circuits, abnormal degradation and lithium over-precipitation. As the industry moves towards more sophisticated battery health management, automakers increasingly rely on BMS technology to proactively monitor and diagnose battery conditions. LG claims its software, currently used by nine global automakers, helps detect and address problems early.

The company is now expanding its collaborations with automakers and ramping up sales of its safety software. Importantly, this software is not limited to vehicles using LG batteries -- it can be integrated into EVs with batteries from other manufacturers as well.

In addition to safety diagnostics, LG Energy Solution has developed advanced tools for predicting battery degradation. By analyzing driving patterns, their BMS software can accurately forecast a battery’s future capacity and health. This predictive capability is grounded in LG’s expertise in battery chemistry, which allows them to model complex degradation processes like lithium plating and electrode wear.

The company also uses AI to refine its diagnostic algorithms, reducing the error rate in battery degradation predictions to just 1 percent, the best in the industry, according to LG. Moreover, the company leverages cloud technology to analyze vast amounts of battery data in real-time. So far, the company has gathered data from 12,000 vehicles, representing about 2.2 percent of all EVs in South Korea.

Looking ahead, LG Energy Solution is developing BMS technology tailored for the next generation of software-defined vehicles. By using the enhanced computing power of system-on-chip technology in these vehicles, LG aims to implement even more advanced battery algorithms and offer new services based on real-time vehicle data.

In March, LG partnered with Qualcomm to develop cutting-edge BMS diagnostic solutions based on SoCs. The company also signed an agreement with US semiconductor firm Analog Devices Inc. to secure a stable supply of high-performance battery management chips and advance technology development.

Meanwhile, competitors like SK On and Samsung SDI are also pushing forward in the BMS space. In 2022, SK On codeveloped a battery management chip in partnership with Autosilicon, a Korean fabless semiconductor company. Samsung SDI is working on a next-generation BMS that can detect battery pack anomalies and predict potential failures, with mass production of batteries featuring this advanced BMS expected by 2025.

![[Today’s K-pop] Blackpink’s Jennie, Lisa invited to Coachella as solo acts](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=644&simg=/content/image/2024/11/21/20241121050099_0.jpg)