|

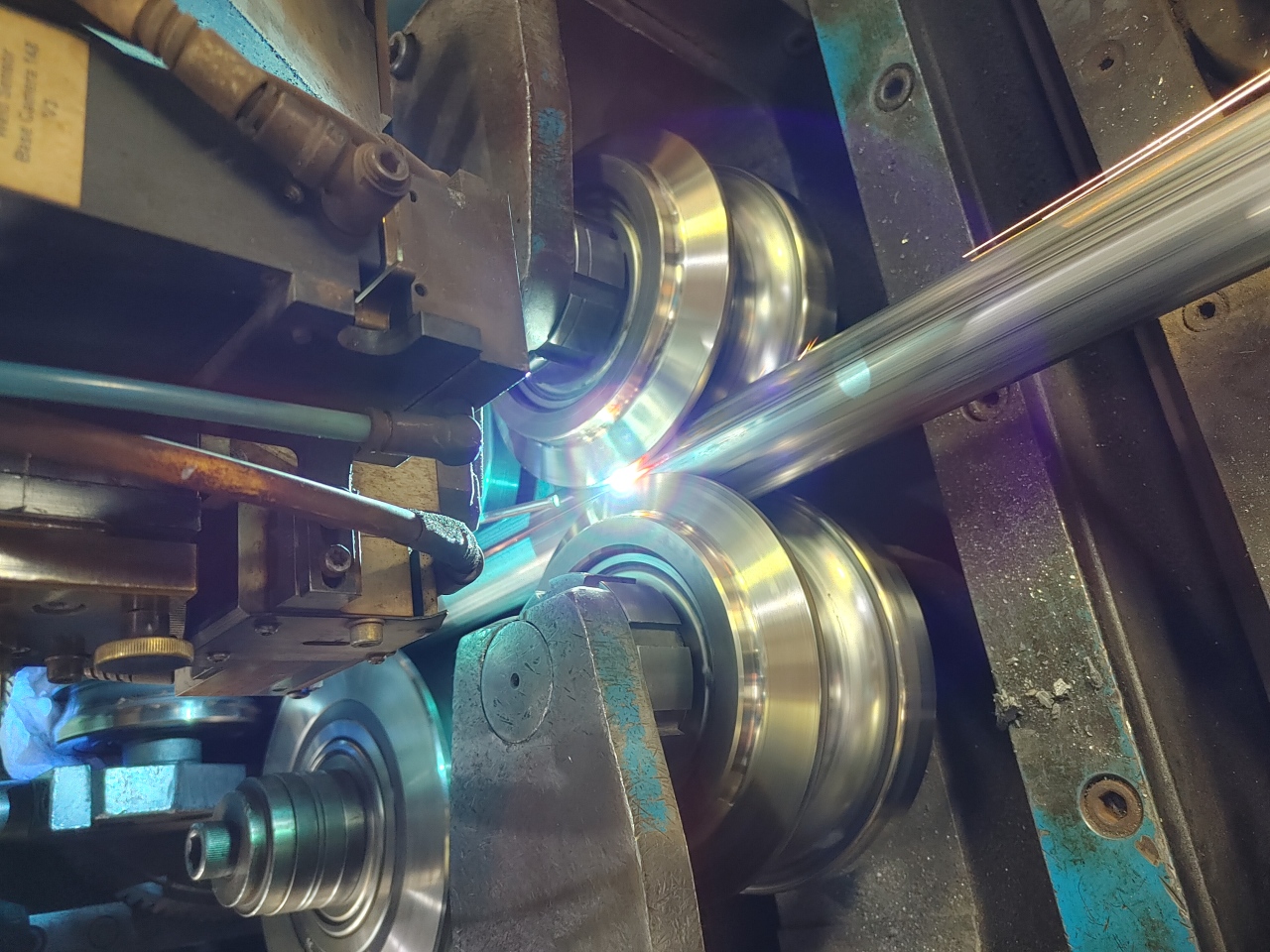

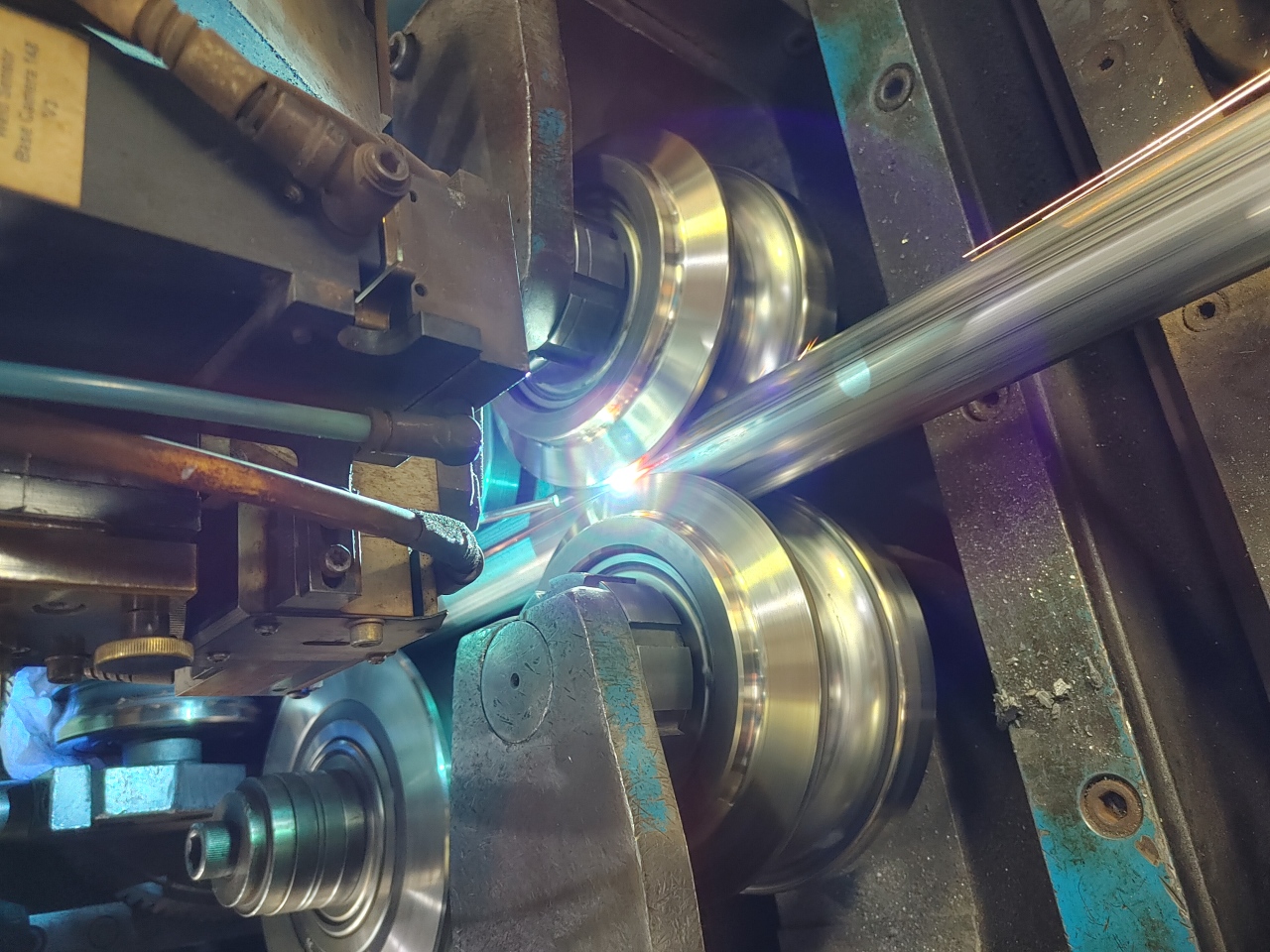

Posco’s high-alloy stainless steel is used to make a heat exchanger tube for a desulfurization facility. (Posco) |

Posco has succeeded in developing core materials used in desulfurization facilities at industrial plants, the country’s largest steelmaker said Sunday.

The company said it has developed three types of high-alloy stainless steel that can be used to make absorbers, gas-gas heaters and zero liquid discharge equipment, all of which can help cut sulfur oxide emissions in industrial plants such as steel plants, oil refineries and thermoelectric power plants.

The new types of steel are specially designed to withstand corrosion under harsh conditions, the steelmaker explained.

Because it is difficult to produce, and there was not as much demand here in the past, all of the materials for desulfurization facilities were previously imported.

But with growing demand for environmentally friendly facilities, Posco said it listened to requests from the local industry to come up with materials to replace imported ones.

Posco chose to create its own materials as an alternative to the imports, and its products turned out more competitive in terms of production costs and delivery times.

“Not only will Posco’s new materials offer the benefit of localizing the imported materials, but we also anticipate that we will support the growth of Korea’s industrial competitiveness in the material parts industry,” Posco said.

Posco said its high-alloy stainless steels have been under development for about two years, have undergone field tests to prove their high quality, and have recently been supplied to a desulfurization facility producer here.

By Jo He-rim (

herim@heraldcorp.com)