Samsung Electronics, the world’s No. 1 television-maker, is expected to be among the global TV manufacturers forced to sell more cell-type LCD panels due to increasing demands from set-makers who are worried about hostile TV market conditions.

“Cell-type panels are soon going to be a substantial trend as more and more set-makers want to reduce costs in the face of the far-from-friendly market conditions,” said one industry source, declining to be identified.

Panel-makers are reluctant to expand cell-type LCD panels because the prices go down significantly compared to the finished modules. This inevitably means that profit margins will be reduced.

Experts say that a shift to cell-based panels would lead to a 30 percent decline in sales.

For this reason, some industry sources said Samsung seems to be reticent to exactly calculate the proportion of their panels sold in the cell-type compared to those sold in the finished module-form.

About half of Samsung’s panels are reportedly shipped to overseas set-makers such as Sony, while the other half are sold to the company’s own set-making business division.

Earlier in January, DisplaySearch, a U.S.-based market research firm, had said up to 40 percent of Samsung’s shipments to its internal television division would be cell-types this year.

It also said that globally, shipments of cell-type panels would rise by 30 percent.

|

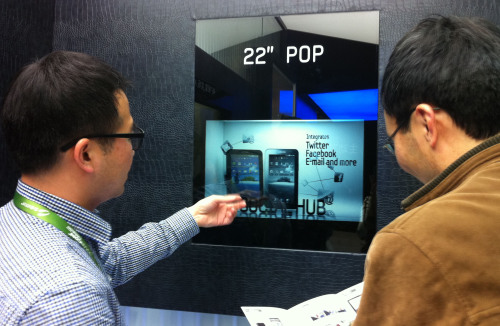

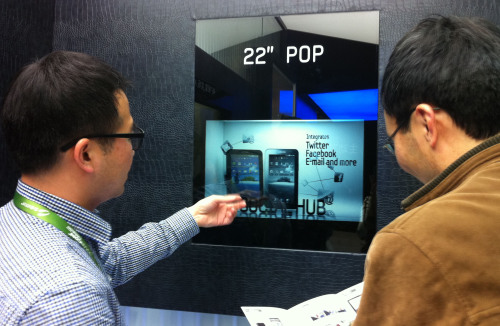

Spectators view the world’s first-ever transparent LCD panels manufactured by Samsung Electronics. (Samsung Electronics) |

Cell-type panels are basically partially-completed panels that include the core liquid crystal cell, but not the backlight module or additional optical films.

Set-makers consequently buy the panels at cheaper prices because they complete the panels as they build the TV sets. They also are able to slap their own brands on the end-products.

The upside of this setup is that the set-makers are able to cut costs.

“Set makers are doing all they can to cut costs because the TV market is not expected to be much better this year after hitting the bottom in last,” said one analyst who declined to identified.

DisplaySearch had previously calculated that set-makers would cut between $5-10 per TV set by using cell-type panels.

Logistical costs can expect to be slashed to about one-fifth of the original amount if the particular firm has manufacturing facilities abroad.

So for the ordinary customer, the cell business could mean a slash in retail prices, or at least that prices would not go further up, industry watchers say.

Due to lackluster demand for new TVs, the television market was likely to continue to falter this year after an equally bad year in 2010, research companies said.

This year, global TV sales were expected to stay almost unchanged at $119 billion, up just slightly from $118 billion last year, according to Daewoo Securities figures.

The unfavorable business climate appeared to be causing even internal rifts between the panel-making and set-making businesses within the mammoth television makers, those close to the matter said.

The clash is caused because while the set-making division would rather receive cell-type panels to slash costs, their panel-making affiliates are reluctant to do so for fear of falling profit margins.

By Kim Ji-hyun (

jemmie@heraldcorp.com)

![[Today’s K-pop] Blackpink’s Jennie, Lisa invited to Coachella as solo acts](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=644&simg=/content/image/2024/11/21/20241121050099_0.jpg)