Three-dimensional printers have long been used to make plastic figurines and industrial parts, but soon, another material might become available through printing technology -- silk protein.

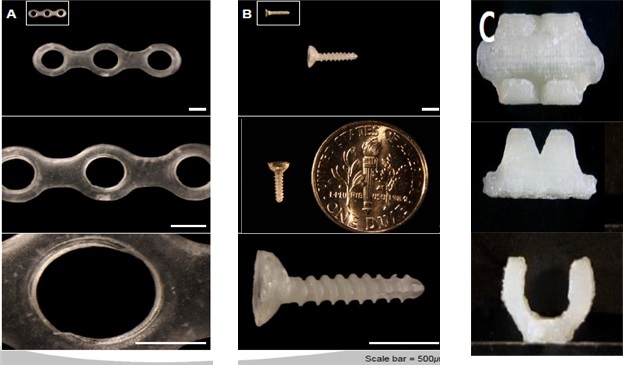

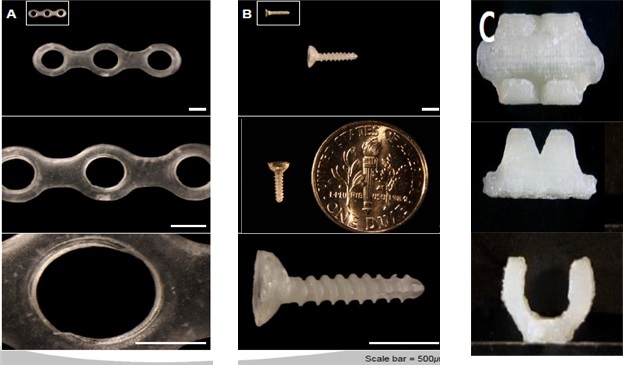

South Korea’s Rural Development Administration said that it has successfully developed a new 3-D printing technology that uses protein extracted from silkworms -- a 25:75 combination of sericin and fibroin -- to print out customized surgical bone plates, screws and clips used to fix bone fractures.

|

Silk protein-based bone plates, screws and clips created using a specialized medical 3-D printer. (Rural Development Administration) |

The RDA’s newly built medical 3-D printer is equipped with specialized nozzles and temperature control features that allow silk protein, a highly-sensitive biomaterial, to be used as a stable source of filament.

It is the first attempt to use silk protein, a biocompatible material already certified for medical use by the US Food and Drug Administration, to create artificial surgical components used to fix broken bones, said the state body dedicated to developing new agricultural technologies.

Currently, metals and synthetic chemicals, which can dissolve in the body, are typically used to create screws, plates and clips used to bind broken bones.

However, these materials have limitations that could be complemented by silk protein, said Lee Jin-mo, director general of the RDA’s National Institute of Agricultural Sciences.

“Metal-based parts are strong, yet must be removed from a patient’s body through secondary surgery. Parts made from synthetic chemicals naturally dissolve in the body, yet they sometimes break down when applied to fragile, rounded bones such as cheekbones,” Lee said.

“In comparison, parts based on silk protein were found to be more flexible, more biocompatible, as well as able to withstand more pressure, making them apt for bone surgeries, particularly those involving round-shaped bones,” he said.

Silk protein could also drive down the costs of bone fracture surgeries, according to the RDA. A surgical plate made of silk protein would cost about 150,000 won ($133), which is about half the cost of plates based on synthetic chemicals already in the market.

Looking ahead, the RDA expects to conduct clinical trials on the effectiveness and safety of silk protein-made bone screws, plates and clips made through 3-D printing technology, with plans to commercialize the new system by next year, Lee said.

If commercialized to success, this patented silk protein 3-D printing technology could significantly drive up demand for silkworms carefully cultivated for medical use -- a business in which Korean farmers already hold a competitive edge, he added.

“Around 100 silkworms are used to make a single surgical bone plate. Given this, we believe that demand for silkworms and mulberry trees (the only food that silkworms feed on) could also greatly increase and boost the local sericulture sector,” Lee said.

The global fracture fixation product market is expected to grow from $6.7 billion as of 2015 to approximately $11.3 billion by 2021, led by the rising number of orthopedic surgeries for osteoarthritis and technological advancements, according to Zion Market Research.

By Sohn Ji-young (

jys@heraldcorp.com)