Posco was named this week as the world’s most competitive steelmaker for the eighth consecutive year, the company said Tuesday, with the leading South Korean steel producer poised to take over the global steel industry with its self-developed premium product giga steel.

|

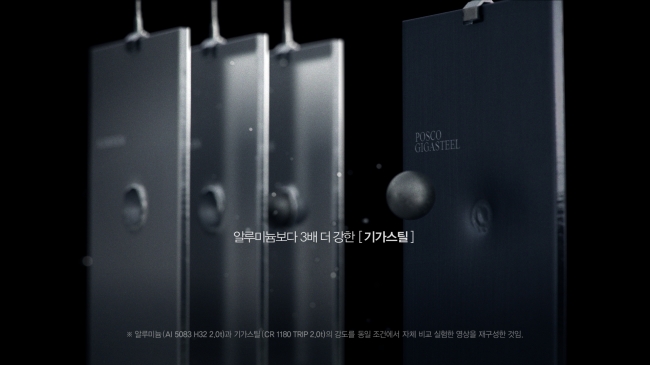

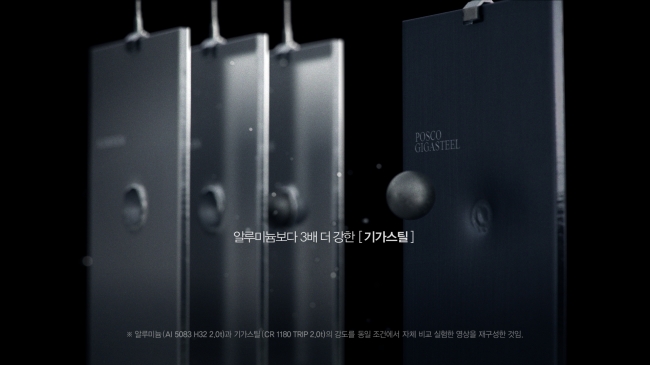

An image of Posco’s television ad for the world premium giga steel. The ad reads “giga steel is three times stronger than aluminum.” (Posco) |

Global steel research firm World Steel Dynamics announced Monday that Posco ranked as the most competitive steelmaker among 37 global steelmakers with 8.31 points on a scale from 1 to 10, evaluated across 23 categories.

Posco’s competitiveness was attributed largely to premium products that helped elevate the company’s portfolio and financial structure.

Premium products are often mentioned as the next locomotive for steelmakers to bolster their performance amid an oversupply of affordable steel made in China and the spread of trade protectionism.

Posco has been moving to maintain its lead with giga steel, which refers to steel with ultrahigh-tensile strength of more than a gigapascal. It can withstand over 100 kilograms per square millimeter, while a 10-by-15-centimeter giga steel plate can withstand 1,500 midsized cars that weigh about a ton each.

Mainly used for automotive steel plates, car frames and other auto parts, Posco’s giga steel was used to make the a-pillar of Renault‘s eco-friendly concept car Eolab. The overall weight of Eolab was reduced by 130 kilograms and reached a fuel efficiency of 100 kilometers per liter by using giga steel and magnesium, Posco said.

Italian carmaker Fiat also applied giga steel to make bumpers.

|

The Posco Body Concept Electric Vehicle, or PBC-EV, is 26.4 percent lighter than previous midsize cars due to giga steel that makes up 45.4 percent of the car frame. (Posco) |

Among 800 steelmakers worldwide, the number of companies that have obtained the technology to produce auto steel sheets remains relatively low at 20. The entrance barrier is higher to produce giga steel, often referred to as “dream steel.”

Posco currently has the capacity to mass-produce eight types of giga steel.

Riding on the successful performance of its world premium products, Posco posted a 2.8 trillion won ($2.46 billion) operating profit, up 18 percent on-year in 2016, the company said.

Giga steel is anticipated to garner more popularity in the near future, as it weighs one-third of aluminum, ultimately reducing the overall weight of cars, the company said. It also emits less carbon dioxide than aluminum during production.

Up to 2.5 kilograms of carbon dioxide is emitted when producing 1 kilogram of steel, while making a kilogram of aluminum creates up to 12.6 kilograms of carbon dioxide, according to data from the World Steel Association.

In terms of price, production cost is 2.1 times more affordable and consumer goods are 3.5 times cheaper when using giga steel instead of aluminum, Posco said.

By Kim Bo-gyung (

lisakim425@heraldcorp.com)

![[Exclusive] Hyundai Mobis eyes closer ties with BYD](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=644&simg=/content/image/2024/11/25/20241125050044_0.jpg)

![[Herald Review] 'Gangnam B-Side' combines social realism with masterful suspense, performance](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=644&simg=/content/image/2024/11/25/20241125050072_0.jpg)