|

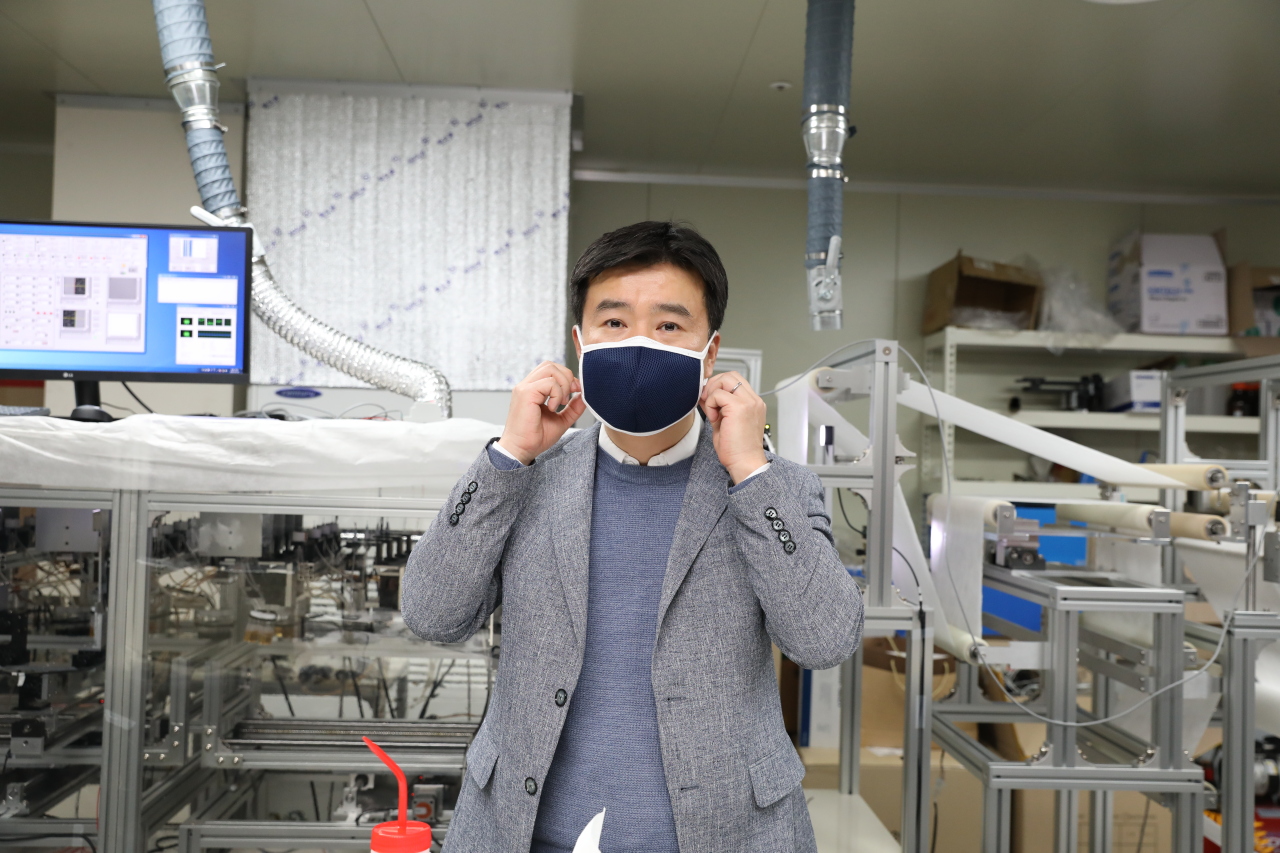

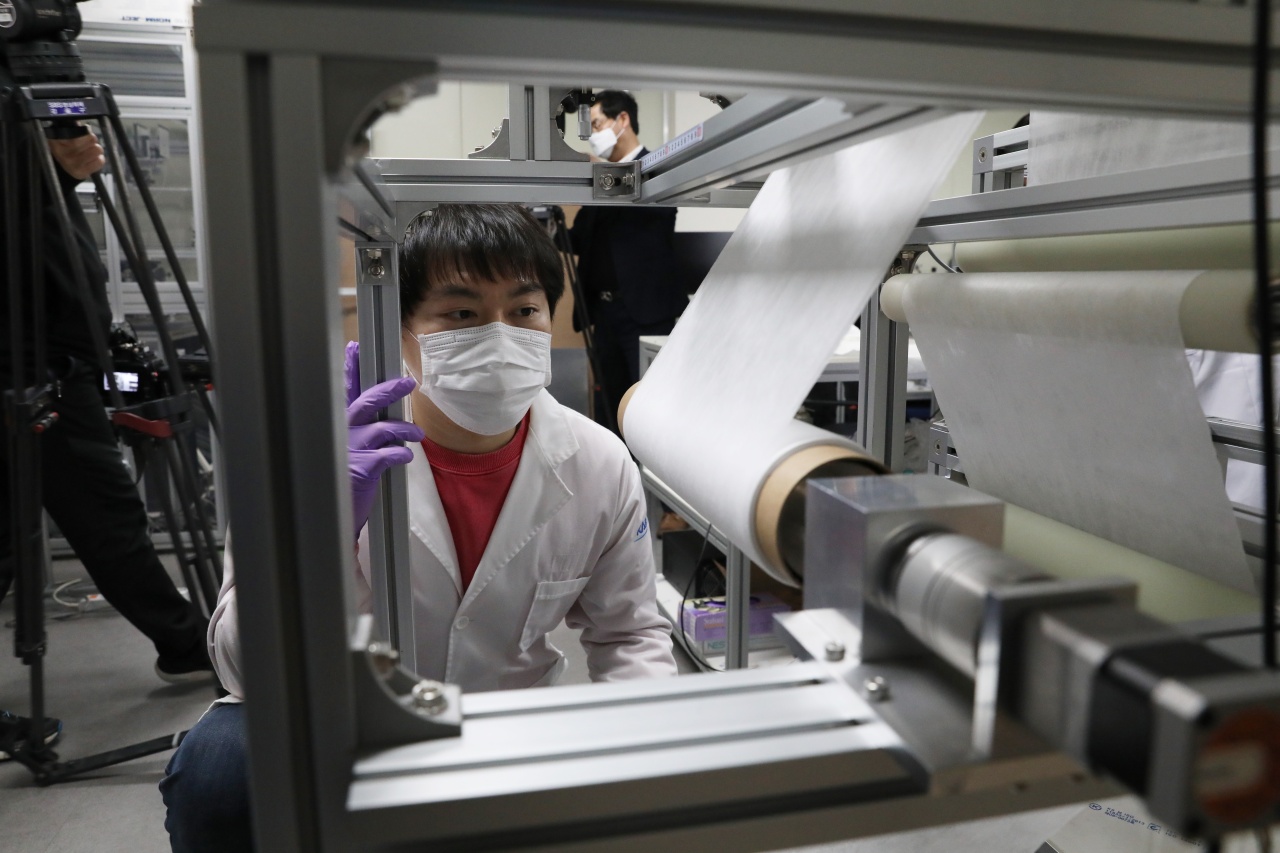

Professor Kim Il-doo of materials science and engineering at KAIST demonstrates wearing the mask his team has developed using nanofabric membrane (KAIST) |

Scientists from the Korea Advanced Institute of Science and Technology said Monday that they have successfully developed nanofabric mask filters that can withstand at least 20 washes and used for a month.

Masks have become a high priority in South Korea since the outbreak of COVID-19. Their scarcity and the opportunistic profiteering that ensued have made the government put a cap on exports, and ration the filter mask purchases to two per person on a weekly basis.

With more people resorting to wearing used masks for several consecutive days, business providers and government authorities are scrambling to secure more filter masks, or filter replacements.

The research team led by Kim Il-doo, professor of materials science and engineering at KAIST, said they have invented washable filters using nanofabric cross-alignment technology.

“This technology will solve the mask scarcity issue and environmental impact of mask waste,” Kim said.

The existing mask filters use electrostatic method, whose effectivity wears off as the static energy on the surface gradually disappears, especially if the mask comes into contact with water.

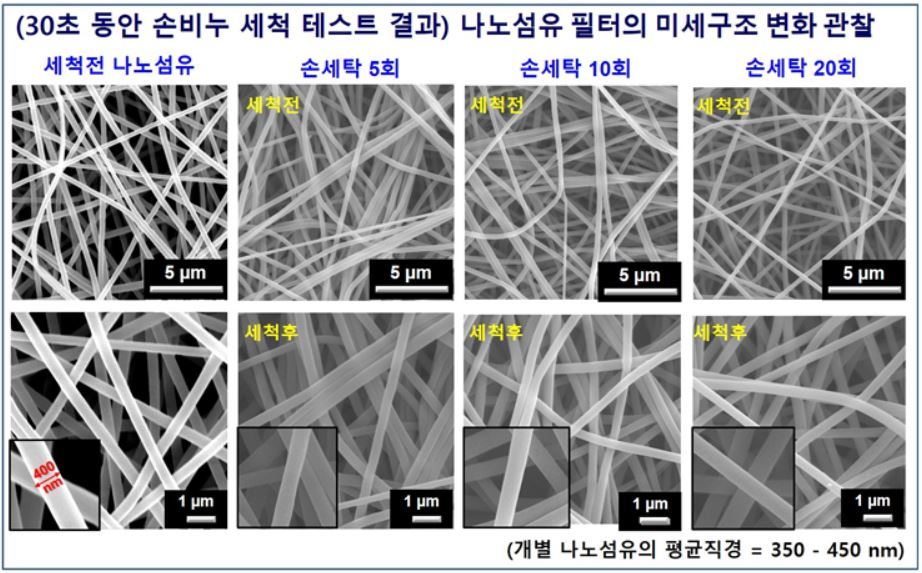

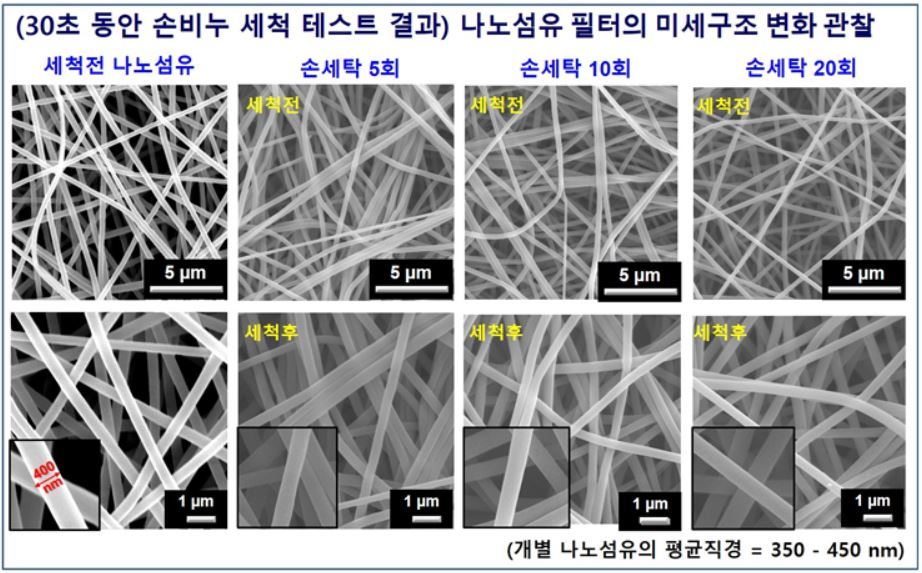

Nanofabric cross-alignment technology developed by Kim’s team, however, ensures KF80 to N95 filtration up to 94 percent after 20 repeated washes. No change occurred to the structure of the nanofabric membrane after tests, according to the team.

|

Comparison of the nanofabric filter before (upper row) and after (lower row) five, 10 and 20 washes (KAIST) |

The mask also withstood 4,000 crumples and stretches and three hours of disinfection in ethanol. The ethanol endurance means that the mask can be used for more than a month, the research team said.

Kim plans to commercialize the mask after acquiring the Drug Ministry’s approval.

Currently, the Il-DOO KIM GROUP, a company founded by Kim in February 2019, has the capacity to produce an average of 1,500 nanofabric mask filters per day.

|

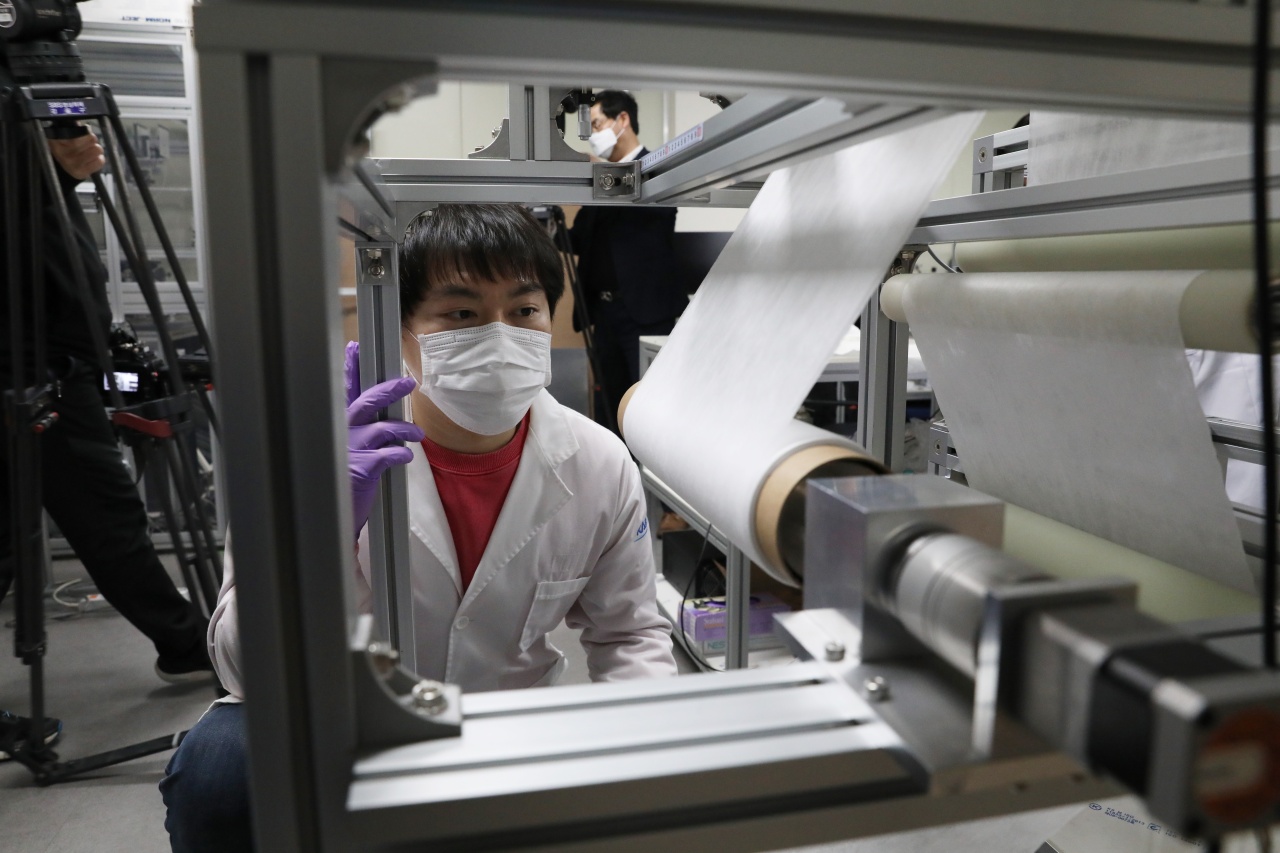

IL-DOO KIM GROUP (KAIST) |