|

Hyundai Motor’s hydrogen charging station (Hyundai Motor) |

The South Korean government on Tuesday signed a memorandum of understanding with Hyundai Motor to deploy its hydrogen vehicles at Jaundae, a military base in Daejeon where a new hydrogen charging station will be built.

According to the memorandum -- signed by Prime Minister Chung Sye-kyun, Environment Minister Cho Myung-rae, Defense Minister Jeong Kyeong-doo, Industry Minister Sung Yun-mo and Hyundai Motor Group President Gong Young-woon -- the military will purchase five hydrogen vehicles, including a high-speed passenger bus under development, and deploy them to the hydrogen charging station at Jaundae. The station, set for completion in the first half of next year, will be the first hydrogen charging station to be shared by the military and civilians.

This is only one of many times that Hyundai Motor has teamed up with the government. On March 20, Hyundai Motor, CJ Logistics, Coupang, the Environment Ministry and the Industry Ministry signed a memorandum of understanding to operate five 10-ton hydrogen trucks to carry payloads between Okcheon, North Chungcheong Province, and Gunpo, Gyeonggi Province, from 2021 to 2022.

So here’s the question: Why are Hyundai and the government pushing for hydrogen vehicles when electric vehicles are already available as an eco-friendly option?

In short, hydrogen vehicles can do what EVs can’t: travel light.

“Compared to hydrogen-fueled trucks, electric trucks can’t secure enough driving range due to their heavy weight. For instance, it takes eight tons of batteries to power a 10-ton cargo truck. In contrast, hydrogen trucks can keep generating energy, which is much lighter than batteries,” a Hyundai Motor official said.

As hydrogen trucks don’t have to give up cargo space for 8 tons of batteries, they become more suitable for retail and logistics businesses.

“Big trucks and buses, which run on diesel, need to be replaced by eco-friendlier vehicles. However, sufficient batteries can’t be loaded on electric trucks and buses because they have to carry payloads. For this reason, hydrogen vehicles are regarded as a more suitable alternative (for logistics),” an industry source said.

“For small trucks below 2.5 tons, electric trucks are more efficient. In case of bigger trucks, hydrogen trucks are more suitable,” a retail industry source said.

Also, for truckers, whose time is gold, short charging times make hydrogen vehicles even more attractive.

According to Hyundai Motor and Samsung Securities, hydrogen vehicles can travel 609 kilometers with a single charge that takes three to five minutes whereas EVs can travel 354 kilometers with a single charge, taking between 20 minutes to as long as eight hours.

To sum up, hydrogen trucks are the only viable option to replace internal combustion engine trucks, which account for 24.2 percent of fine dust emitted by vehicles in Korea, according to the Industry Ministry.

Drawbacks of hydrogen facilities

However, though Korea aims to have installed 1,200 hydrogen charging stations by 2040 as part of a hydrogen transition, the ambitious plan is already being stalled by safety concerns from worried residents.

On May 14, Busan Metropolitan City held a seminar for local residents to explain the safety of a hydrogen charging station to be operational in the second half of this year. However, officials didn’t get the chance as the event ended abruptly.

“The seminar got overheated. Local residents got emotional and just said no. It ended without any explanation,” a Busan City official said.

The residents were mostly concerned about explosions. Hydrogen is 10 times more explosive than liquefied natural gas, they say. This claim contradicts Korea Gas Safety Corp. data indicating that gasoline, liquefied petroleum gas and LNG are 1.44, 1.22 and 1.03 times more dangerous than hydrogen, respectively.

“Experts say hydrogen is safe, but if it explodes, the whole area will blow up. How do you expect us to live amid such risks?” a local resident said at the seminar.

The residents cite a hydrogen tank explosion at a research facility in Gangneung, Gangwon Province, in May last year that killed two people and injured six.

A year later, loopholes in the safety inspection system show that there is still cause for concern.

Though high-pressure facilities such as hydrogen storage tanks, pipelines and dispensers have to be managed tightly under the High-Pressure Gas Safety Control Act, low-pressure facilities such as hydrogen production and extraction facilities -- which can be still dangerous if linked to high-pressure facilities -- are in a regulatory blind spot.

Currently, inspectors from the Labor Ministry check low-pressure facilities at hydrogen charging stations “of their choosing” under the Occupational Safety and Health Act.

“Labor inspectors mainly check low-pressure facilities at big hydrogen facilities, so small ones are left out,” a government official said.

According to the Labor Ministry, labor inspectors draw up safety reports every four years on low-pressure hydrogen facilities that treat, produce or store 50 metric tons or more of hydrogen.

Then, facilities that have been assigned high safety ratings are checked every four years, while those with medium ratings are checked every two years and those with low ratings are checked every year.

The loopholes won’t be closed anytime soon.

“Talks are underway to revise the High-Pressure Gas Safety Control Act and apply the law to low-pressure hydrogen facilities linked to high-pressure ones,” a KGSC official said.

For low-pressure hydrogen facilities that aren’t linked to high-pressure facilities, Korea passed relevant laws in January to bolster safety standards. The law, however, will take effect in 2022, according to another KGSC official.

Safer than LNG?

Unlike low-pressure hydrogen facilities, high-pressure ones are under tight control.

Under the high-pressure gas safety law, staff stay at hydrogen charging stations and monitor high-pressure facilities 24/7.

High-pressure hydrogen facilities are designed and manufactured in accordance with International Organization for Standardization, or ISO, standards. As such, they have to pass pressure and airtightness tests at a pressure level of 150 percent. Also, they have to be thick enough to pass tensile tests at a pressure level of 200 percent.

In terms of software, hydrogen charging stations are equipped with sensors to detect hydrogen gas leaks just in case.

“Sensors can detect hydrogen gas leaks and send alarms when the density of hydrogen gas in the air reaches 25 percent of the minimum concentration level of explosion,” an H2 Korea official said.

“They can also detect sparks and cut off hydrogen gas from flowing inside the pipes right away.”

As for the nozzles of hydrogen gas dispensers, they are designed to interlock perfectly with vehicles, and infrared receivers at the nozzles communicate with infrared emitters of fuel caps of vehicles to ensure safe refueling.

Hydrogen tanks inside vehicles have to pass 17 safety tests, which require them to be strong enough to withstand weight equivalent to that of the Eiffel Tower.

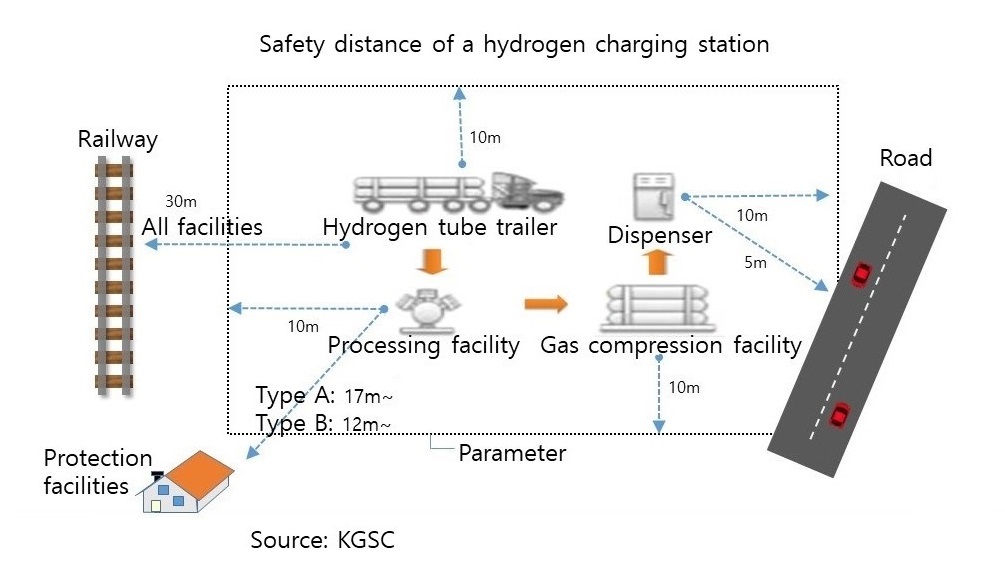

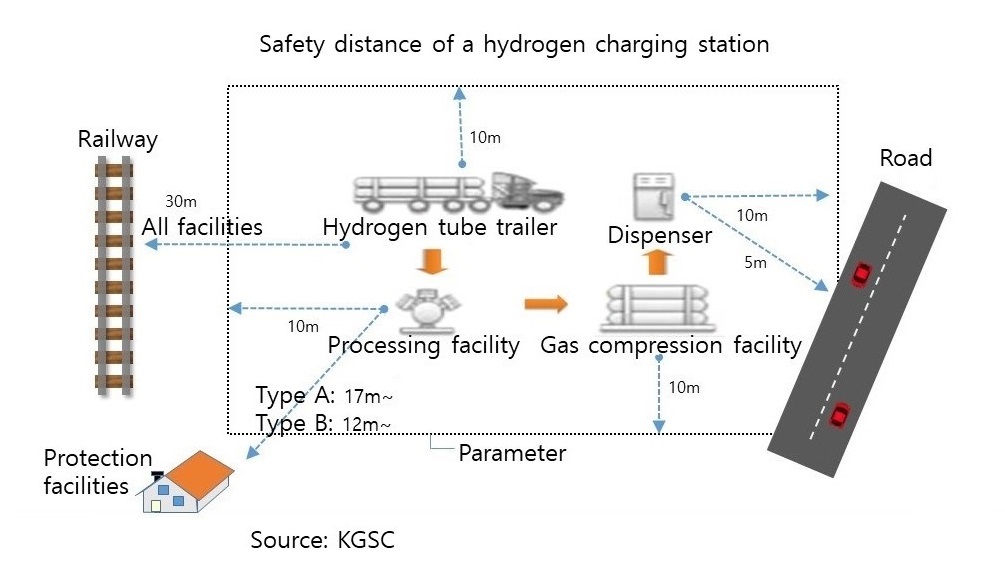

Also, hydrogen charging stations must be located at least 17 meters away from type A protected facilities including schools, kindergartens and playgrounds and 12 meters from homes. Firewalls and explosion-proof walls are installed as failsafe measures.

Above all, hydrogen is safer than the natural gas used in kitchens, experts say.

“Hydrogen is 14 times lighter than air, so it disperses immediately, reducing the risk of fire. It doesn’t emit toxic gas unlike other fuels, so there are fewer risks of asphyxiation. Some people conflate hydrogen energy with hydrogen bombs, but the two are completely different in components and mechanisms,” an Industry Ministry official said.

Currently, France has a hydrogen filling station for taxis near the Eiffel Tower in Paris while Japan has one right next to its famous Tokyo Tower.

By Kim Byung-wook (

kbw@heraldcorp.com)

![[Today’s K-pop] Blackpink’s Jennie, Lisa invited to Coachella as solo acts](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=644&simg=/content/image/2024/11/21/20241121050099_0.jpg)