|

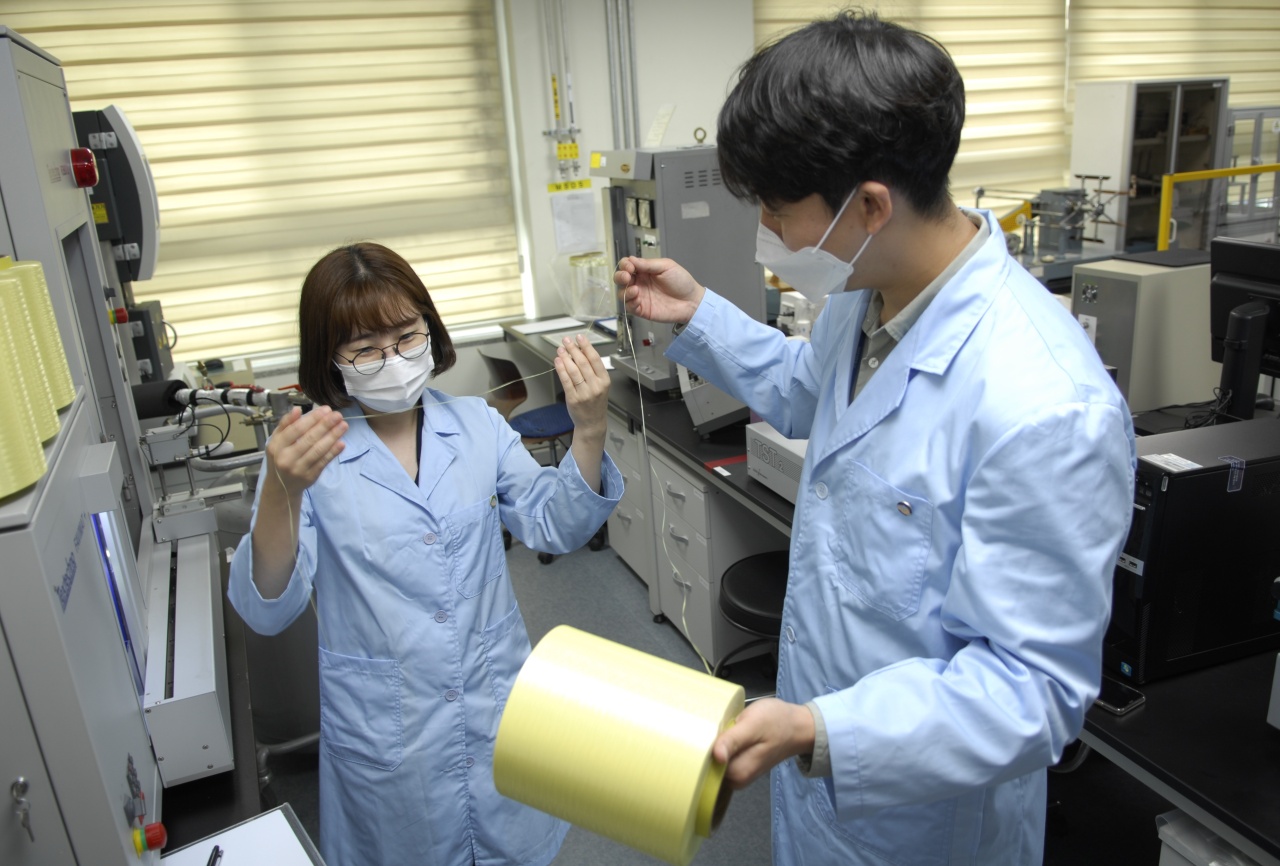

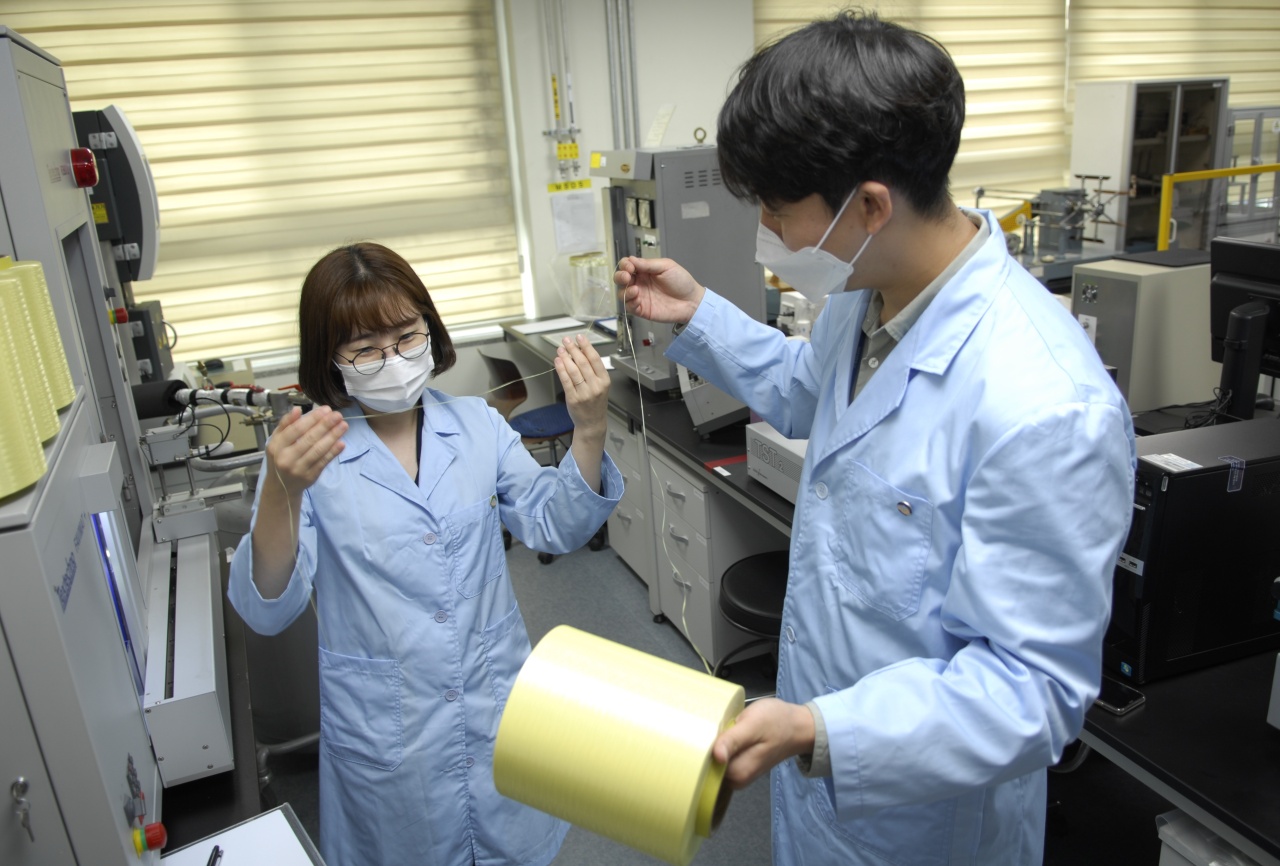

Kolon Industries officials check the company’s aramid fibers. (Kolon Industries) |

Kolon Industries said Thursday it will inject 236.9 billion won ($208.6 million) to double the annual production capacity of aramid, a key raw material for fifth-generation network cables and electric vehicles, from the current 7,500 metric tons to 15,000 tons by 2023.

According to the textile and chemical unit of Kolon Group, this is the second three-year expansion of its aramid plant in Gumi, North Gyeongsang Province. From 2017 to 2020, the company expanded the facility’s capacity 50 percent from 5,000 tons to 7,500 tons.

Aramid is a thin yellow fiber that is lighter but five times more durable than steel. Aramid fibers don’t melt at extremely high temperatures above 500 degrees Celsius. Despite its light weight, an aramid thread just 5 millimeters thick can lift a 2-ton car.

Due to such features, the material has recently gained attention of 5G and EV industries. 5G cables have to stay straight because glass fibers are inside them. Telecommunications firms utilize aramid yarn to wrap internal components of 5G cables to prevent them from sagging.

Also, a layer of aramid can replace a layer of steel wires inside tires. This makes tires lighter and stronger, ideal for EVs that have to reduce as much weight as possible to make space for batteries inside.

“Kolon Industries is considering additional mid- and long-term investments,” a company official said.

By Kim Byung-wook (

kbw@heraldcorp.com)

![[Today’s K-pop] Blackpink’s Jennie, Lisa invited to Coachella as solo acts](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=644&simg=/content/image/2024/11/21/20241121050099_0.jpg)