|

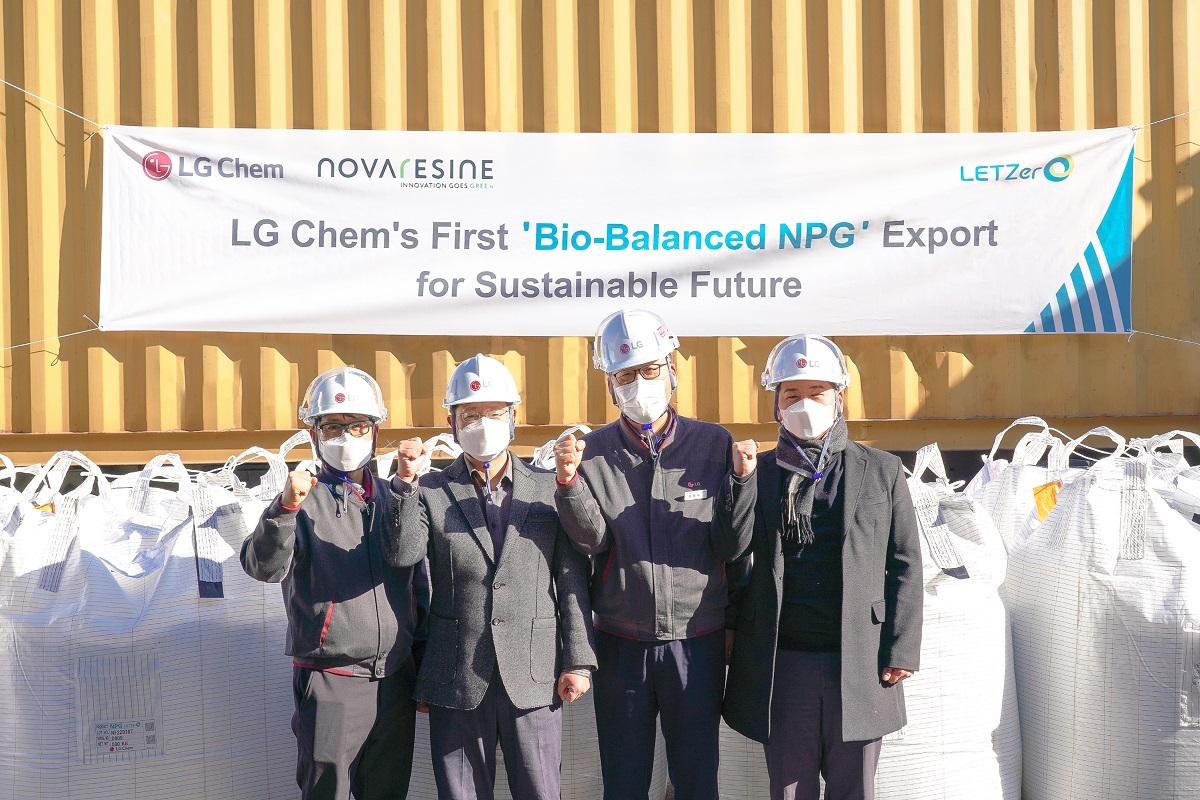

LG Chem officials celebrate the first shipment of eco-friendly coating material NPG at its plant in Yeosu, South Jeolla Province, on Tuesday. (LG Chem) |

Recycled materials are no longer expensive products for a niche market as major South Korean chemical firms roll up their sleeves to introduce them into the daily lives of average consumers.

According to LG Chem Tuesday, it has completed the first shipment of a coating material made of bio raw materials such as waste cooking oil and palm residues. The material, named neopentyl glycol, or NPG, is used to coat cars, consumer electronics and drink cans.

LG Chem’s eco-friendly NPG, manufactured at its plant in Yeosu, South Jeolla Province, will be shipped to Italy where a local company Novaresine will use the material to coat cans and coils.

“A life cycle assessment, verified by the Korean Society of Life Cycle Assessment, showed that LG Chem’s eco-friendly NPG emits carbon 70 percent less than typical NPG,” a company official said.

LG Chem was the first Korean firm to localize NPG in 1998. Its NPG has recently received a global sustainability certification International Sustainability & Carbon Certification Plus, or ISCC Plus.

Meanwhile, SK Chemicals announced Tuesday that it has commercialized chemically-recycled PET products for the first time in Korea, according to the company.

|

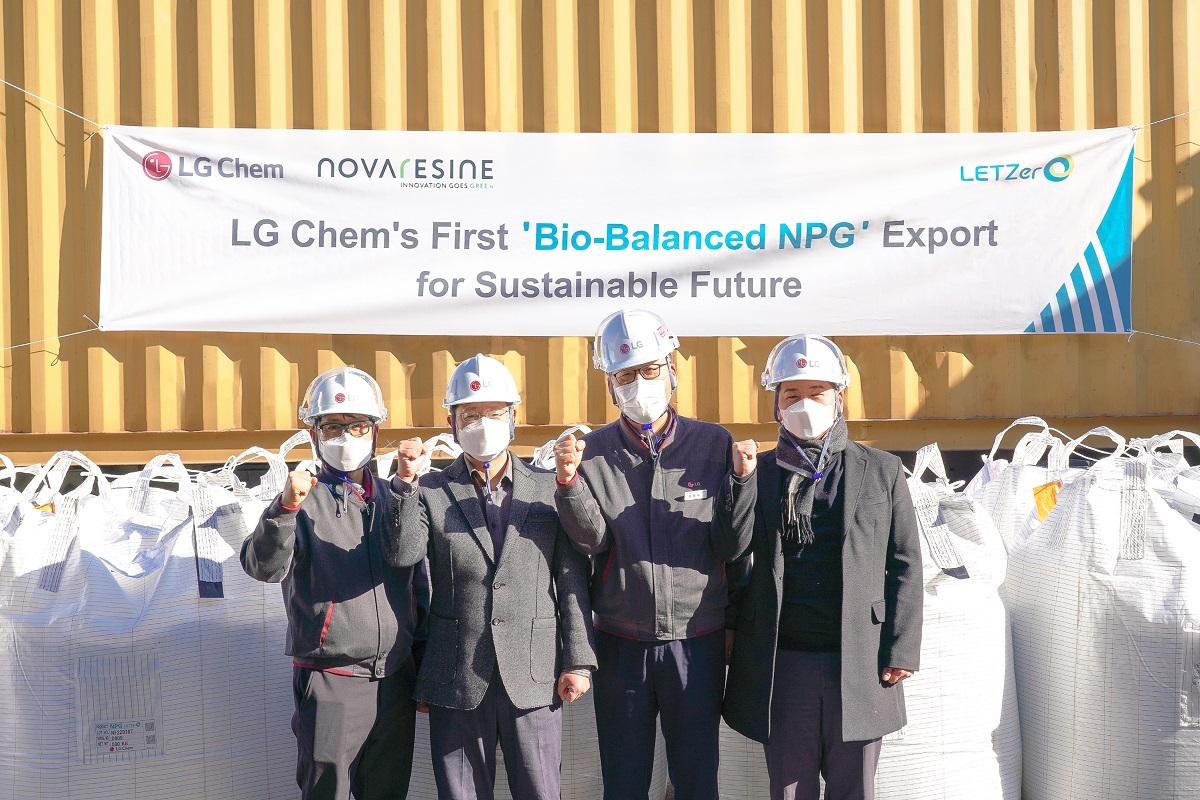

SK Chemicals‘ plastic bottles made of chemically-recycled PET materials. (SK Chemicals) |

Using a technology called depolymerization, SK Chemicals turns waste PET bottles into new PET materials. With recycled PET materials, SK Chemicals will produce and supply plastic cutleries starting this month as demand for disposable spoons and forks soar amid the pandemic.

“Last month, the Korean government announced a circular economy plan that mandates domestic plastic manufacturers to use recyclable materials starting next year. In the case of PET, 30 percent of its raw materials should be recyclable by 2030. This would trigger demand for 150,000 metric tons of recyclable PET materials per year in 2030. SK Chemicals will increase the production of recyclable PET depending on the market situation,” a company official said.

By Kim Byung-wook (

kbw@heraldcorp.com)

![[Today’s K-pop] Blackpink’s Jennie, Lisa invited to Coachella as solo acts](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=644&simg=/content/image/2024/11/21/20241121050099_0.jpg)