|

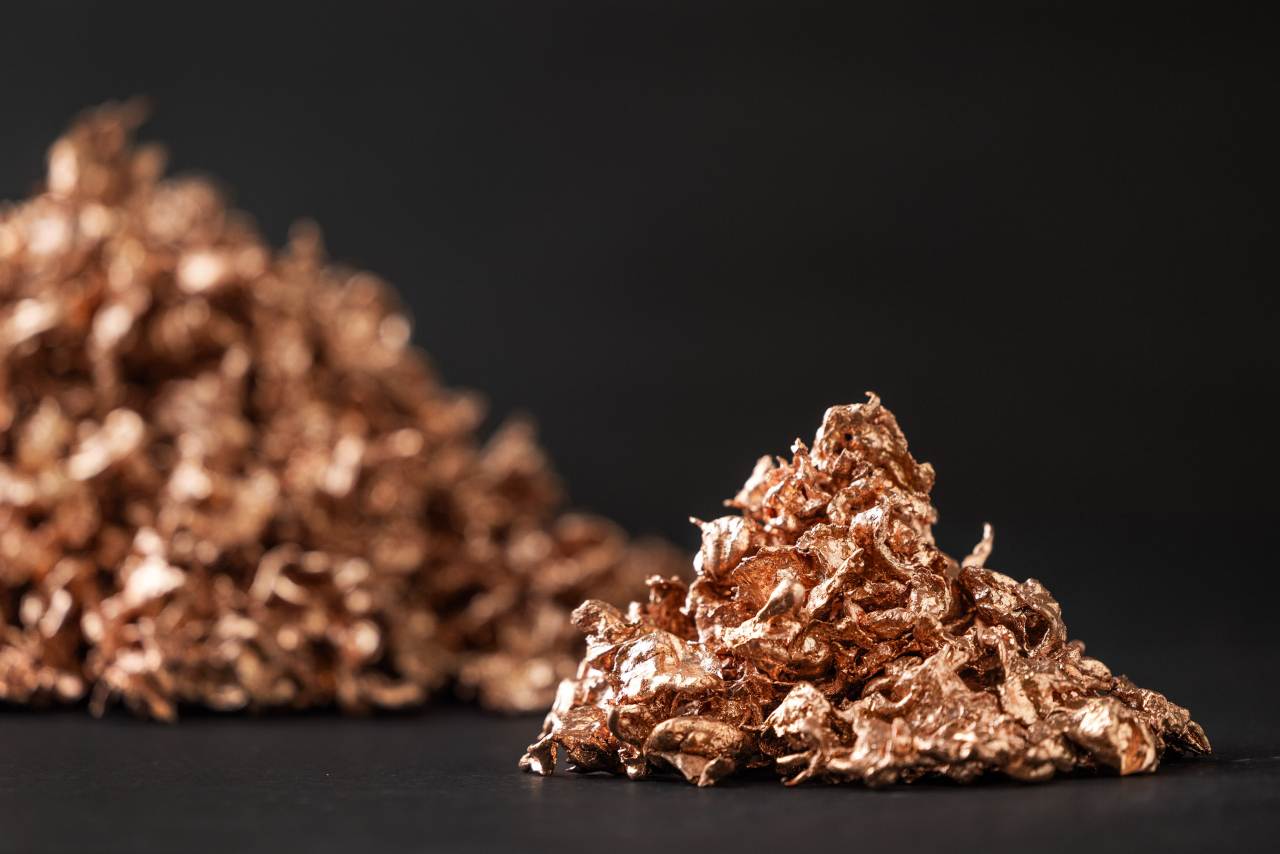

CuFlake, the world's first new raw material for copper foil developed by LS Cable & System. (LS Cable & System) |

LS Cable & System, South Korea’s leading cable manufacturer, said Wednesday that it has become the first in the industry to develop a new raw material for copper foil, accelerating its expansion into rare earth element and green businesses.

CuFlake marks the world’s first case of utilizing copper metal pieces instead of copper wire to produce copper foil which is widely used in electric vehicle components and mobile gadgets.

The company recently completed a successful sample testing of the new material with its copper foil manufacturer.

“We expect to commercialize CuFlake as early as next year and achieve annual sales of over 100 billion won ($76 million)," an LS Cable & System official added.

According to the company, the new material requires fewer processing steps, greatly reducing manufacturing costs.

Typically, copper wire needs to undergo four or five processing steps to remove impurities from copper scraps. CuFlake, on the other hand, can be used directly to produce copper foil after removing impurities from dissolved copper scraps and shaping them into pieces.

Additionally, unlike copper wire which only uses top-grade copper scrap, CuFlake can be made with lower-grade scrap, resolving the issue of limited copper supply.

“Over the last 60 years, we have accumulated our world-class expertise and technology in processing metals including copper and aluminum, the essential raw materials for electric cables," an LS Cable & System official said.

"Going forward, we plan to expand our footprint in eco-friendly markets including copper foil manufacturing, rare earth elements and aluminum components for EVs.”

![[Exclusive] Hyundai Mobis eyes closer ties with BYD](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=644&simg=/content/image/2024/11/25/20241125050044_0.jpg)

![[Herald Review] 'Gangnam B-Side' combines social realism with masterful suspense, performance](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=644&simg=/content/image/2024/11/25/20241125050072_0.jpg)