|

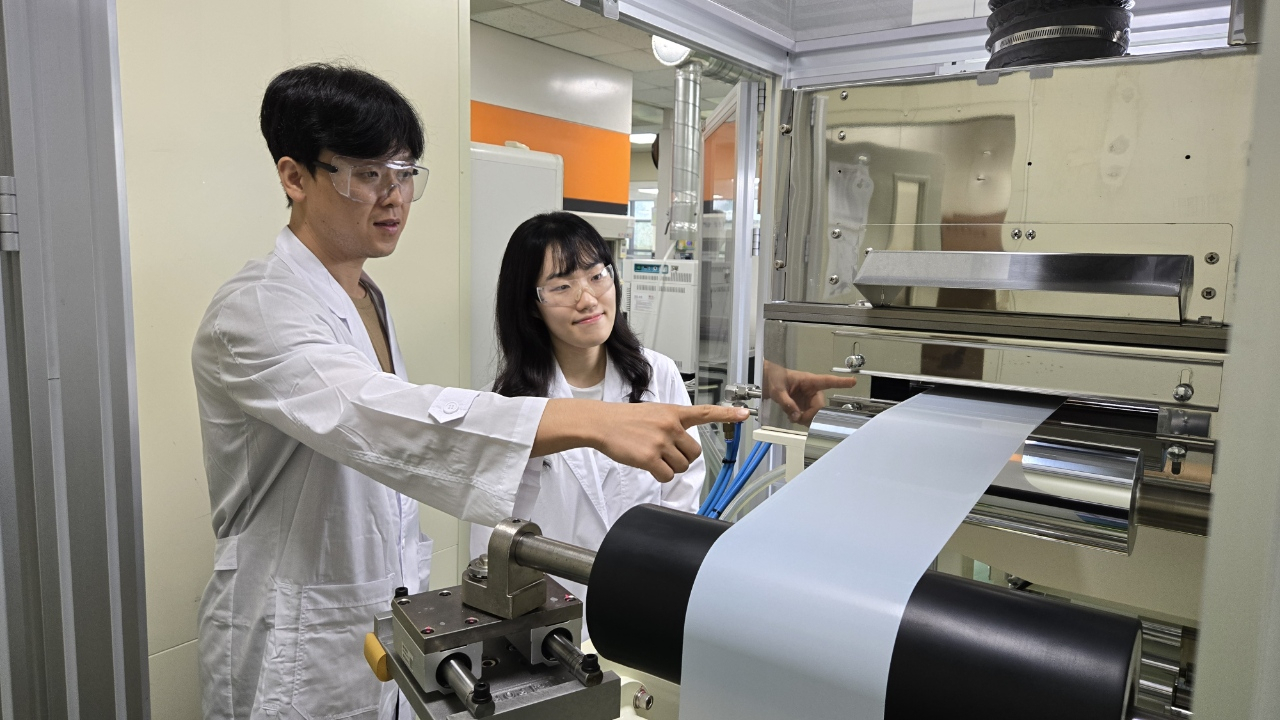

Researchers at SK IE Technology assess battery separators in the lab at the company's R&D center in Daejeon. (SK Innovation) |

DAEJEON -- “You shouldn’t be looking at your smartphones while you are walking around the (SK) R&D campus,” said Lee Su-hyun, group leader of the management support department at SK IE Technology, a battery materials subsidiary of SK Innovation, as he greeted a group of reporters at the SKIET Research and Development Center on Friday.

“We have this rule called SGR meaning Safety Gold Rule on this research site to discourage employees from looking at their smartphones while walking. You can answer calls but no text messaging or sending Kakaotalk messages on the move.”

Reemphasizing safety on SK’s Daejeon campus, a 30-kilometer-per-hour speed camera was installed at the entrance of the R&D facility. Lee explained that if the speed camera catches someone, that person’s supervisor would be notified and it would negatively affect their performance track record.

As much as safety was reiterated throughout the R&D campus with standing boards illustrating SGR, they echoed how SKIET has placed the utmost importance on the safety of its technology in the development of battery separators.

SKIET opened its R&D campus for the first time to press members as the company showcased the development of the world’s first high-heat-resistance separator that can handle up to 350 degrees Celsius to prevent fires in a lithium-ion battery.

SKIET has underscored developing technologies and registering over 300 patents across the world to secure the lead in the advancement of separators that can prevent short circuits, which could cause a fire or an explosion in an EV in case of a contingency.

“We are conducting assessments with a couple of clients (in terms of the 350-degrees-high-heat-resistance-separators),” said Kim Jin-woong, head of SKIET’s R&D center.

“And obviously, as the (newly-developed) separators’ heat resistance is a lot higher than that of the products in the market, we have been getting positive feedback from clients …in terms of cost, we have developed the technology that does not impact our initial raw costs as we can use the existing production lines to roll out the new separators and it enhances our marketability by a margin.”

|

Kim Jin-woong, head of SK IE Technology's R&D center, speaks to reporters at the R&D center in Daejeon on Friday. (SK Innovation) |

Battery separators play a critical role for EV battery makers as they can not only prevent fires but also enhance performance in metrics including the energy density and driving distance -- the thinner they can be, the better. SKIET operates demo plants, which are smaller versions of its actual manufacturing sites, at the Daejeon R&D center to test and develop new technologies.

“The technologies of SKIET’s coating, stretching and developing and applying new materials since 2003 have accumulated our know-how of separator-related technologies,” said Kim.

“SKIET has completed the development of high-heat-resistance (separators) and high-intensity (separators) … We have been enhancing our technological capabilities to a top-class level worldwide with a focus on advancing battery safety and performance.”

SKIET highlighted that its newly developed high-pressure separator, which has a 20 percent higher strength than the existing model in the market, has undergone analysis by potential customers as battery makers look for safer materials in their products.

As for the newly-developed separator technologies, SKIET said it has been able to maintain the cost of the materials as it utilizes the existing processes instead of using high-cost materials, therefore allowing the company to have a better position in the global market now and in the future.

SKIET has also been trying to develop lithium-ion battery separators that do not require a ceramic coating, which would save costs, s as well as separators featuring a thinness of one micrometer or less to secure the lead in the future EV battery sector.

According to Precedence Research, the global battery separator market was estimated at $10.49 billion in 2023 and is expected to reach $54.71 billion by 2034 with a compound annual growth rate of 14.5 percent. SKIET ranked fourth among the top battery separator firms in the world in 2022 as the Korean company accounted for 6.6 percent of the total production.

“We will try to expand supply to various major global clients based on our technological capabilities that exceed our clients’ demand,” said Kim.

|

SK IE Technology's research lab at its R&D center in Daejeon (SK Innovation) |